The quality of the welded stainless steel welded pipe is the focus of purchase users. Its quality is mainly composed of its own materials, standards, wall thickness, welds and other factors. The quality of steel pipes is mainly measured by the same materials and standards. And welding quality.

Welding welded stainless steel is widely used, we usually see support, water pipes and other projects, but the problem is to use high-quality stainless steel straight welded pipes, these projects will be affected, resulting in more serious direct impact on human safety.

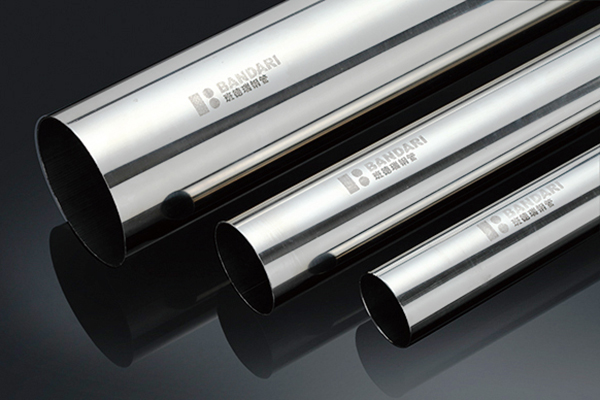

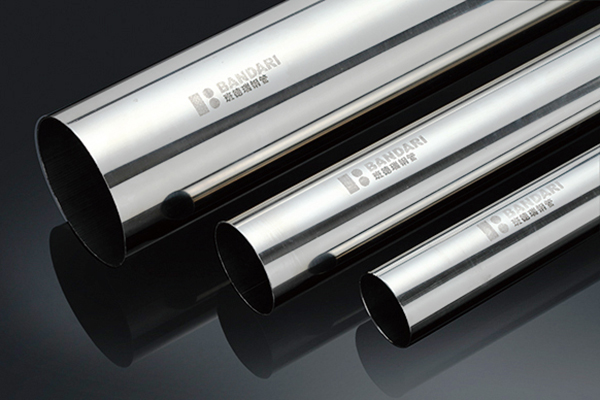

At present, the wall thickness of straight-cut welded stainless steel pipes is generally low, so the lower difference range is better than the lower difference range, and the pressure load capacity is strong. Welding quality is mainly seen through eye or defect inspection. Sand holes and even welds are high-quality products. According to its own structural characteristics, stainless steel straight seam welded pipes have two main uses:

First, it is used to transport liquids, such as water supply and drainage;

Secondly, based on the superior corrosion resistance of the welded straight stainless steel pipe, it can also be used to transport gas and oil and other chemical substances.

The factory uses SUS304 and SUS316 materials, with superior performance. The products have good pressure resistance, corrosion resistance, and protection of health and the environment. The product meets the requirements of GB / T12771-2008, ASTM A554, ASTM A312, EN10312, JIS G3448 and other standards. It is widely used in cold water heating systems, heat exchange systems and piping systems in environmental protection, energy and petrochemical industries for industrial and civil buildings. From the acquisition of raw materials, from the production process to production testing, we have a complete process. Our products are widely used in hotels, natural gas, municipal, fire, food, cruise, construction and other projects.